Ensuring Safe And Reliable Operations – The 2025 Turnaround At Prax Lindsey Oil Refinery

At Prax Lindsey Oil Refinery, like all of our operational assets across the Prax Group, maintaining our assets and equipment is essential for ensuring safe and reliable operations. Earlier this year, the 2025 Turnaround – known as a TAR – was launched at Prax Lindsey Oil Refinery.

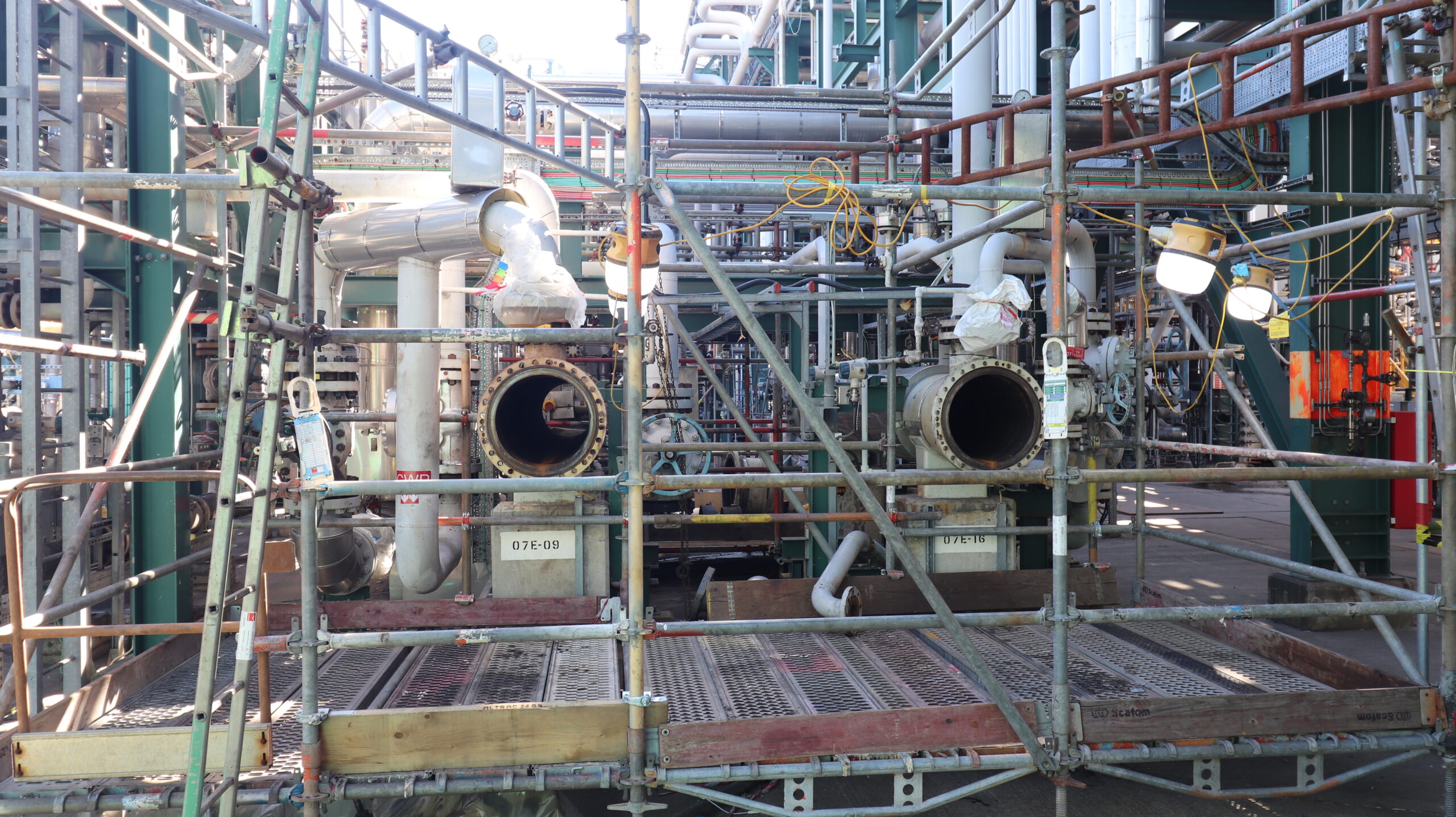

Turnarounds are scheduled periods when refinery units temporarily shut down their operations to perform maintenance, inspections, and upgrades. This is essential to ensure the safety, efficiency, and longevity of the equipment.

During a turnaround, several key activities take place:

- Inspection and Cleaning: The unit is thoroughly inspected for any signs of wear and tear.

- Catalysts: Turnarounds give an opportunity to replace catalyst inventories where required, to maintain unit performance.

- Repairs and Upgrades: Any damaged components are repaired or replaced. Upgrades are also made to improve efficiency and reduce emissions.

- Testing and Calibration: After maintenance, the unit is tested and calibrated to ensure it operates correctly and safely.

The 2025 TAR was completed accident-free, a testament to the dedication, meticulous planning and safety mindsets of everyone involved. Over 200 additional contractors supported the event, contributing to the completion of an impressive 70,000 work hours. All safety targets were achieved, resulting in a fantastic event delivery for all involved, and an event that the entire team is proud of. A huge thank-you goes to everyone involved at Prax Lindsey Oil Refinery for a successful maintenance event!